The Advantages of CNC Turning for Industrial Production

CNC turning has become a critical pillar in modern machining processes, offering unmatched precision and enhanced efficiency for industrial production. During turning operations, metal parts are shaped with millimeter-level precision thanks to automation and the advanced technology of turning centers. These sophisticated machines allow for the creation of complex parts, perfectly meeting even the most stringent design requirements. In this article, we explain the advantages of CNC turning and how it is revolutionizing manufacturing processes across various industries.

What is CNC Turning?

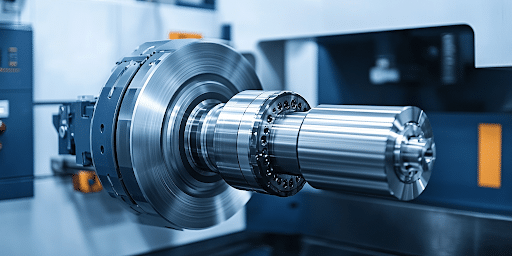

CNC (Computer Numerical Control) turning is an automated turning process in which a metal or plastic component is machined to achieve a precise shape. This process occurs in a turning center, a specialized machine tool that spins the part at high rotational speeds using motorized spindles. While the component rotates, a cutting tool is applied to its surface to remove material, altering the diameter, length, and shape of the component to meet exact design specifications.

CNC turning is especially well-suited for mass production of cylindrical or conical parts, where consistency and precision are essential. Thanks to digital control, each machined part is identical to the previous one, ensuring consistent quality in mass production. This process not only creates parts with high precision but also reduces manufacturing time and costs while delivering an impeccable surface finish.

Outsource Your Industrial Operations

Groupe Hyperforme: How Does CNC Turning Work?

CNC turning is an automated manufacturing process that uses computer-controlled machines to produce components with precise dimensions. Here are the main steps in the turning process:

- Electronic Design: The process begins by creating a digital model of the component to be machined using computer-aided design (CAD) software. This step defines the exact measurements, diameters, and all complex details of the component.

- CAM Programming: Once the design is complete, the data is transferred to a computer-aided manufacturing (CAM) program, which generates instructions for the CNC machine. This CAM program translates the component’s dimensions and specifications into precise commands for the automated tool.

- Machine Setup: The raw component is mounted on the CNC machine, aligned with the main spindle’s rotation axis. The machine is configured according to the computer programs to ensure the cutting movement and rotational motion are perfectly synchronized.

- Component Turning: During production, the part rotates around its axis while the automated tool performs cutting movements to remove material and shape the component into its final form. This step ensures that exact diameters and smooth finishes are achieved, precisely following the electronic design model.

- Quality Control: Once the component is machined, it is inspected to verify that it meets the exact specified measurements, including diameter precision, finishes, and other critical characteristics.

In summary, CNC turning is an efficient production process that reduces manufacturing costs and improves component quality with precise dimensions and measurements, while minimizing human errors and secondary operations.

Simplify Your Industrial Operations with Hyperforme Group

CNC Turning vs. CNC Milling

CNC turning and CNC milling are two essential techniques in precision machining, but they differ in the specific operations they perform and the types of parts they produce.

CNC Turning:

- The part, usually metal, is rotated at high cutting speeds by spindles.

- The cutting tool remains static, removing material to shape the part.

- Ideal for producing cylindrical or conical components with low error tolerance.

- Commonly used in machining centers for parts such as shafts, rings, and screws.

- Less risk of errors due to the simplicity of linear movements.

CNC Milling:

- Uses a rotating tool to remove material from the part, which generally remains stationary.

- Enables the machining of complex surfaces such as holes, grooves, and pockets.

- A more flexible option for creating various shapes and cavities.

- More complex, with a higher risk of errors, especially with tight tolerances.

- Commonly used for parts requiring complex geometries in machining centers.

These two techniques are often combined in modern machining centers to offer a complete material removal solution, meeting the varied needs of the industry for both CNC turning and milling.

Boost Your Efficiency by Partnering with Groupe Hyperforme

Industrial Outsourcing: CNC Turning Methods

CNC turning is a versatile machining technology that offers a variety of methods for machining parts with high precision, depending on project specifications and tolerance requirements. Here’s an overview of the main CNC turning methods, incorporating various cutting tools and advanced techniques to meet the most complex needs:

Taper Turning

Taper turning is used to create conical surfaces by adjusting the cutting tool angle or modifying the feed rate of the part. This process is ideal for machining parts where the maximum diameter varies along their length, such as cones or tapered shafts. Taper turning is commonly applied in production series requiring complex components with varied geometries and strict tolerance requirements.

Vertical Turning

Vertical turning is a method where the part is mounted vertically on a machine, allowing for efficient machining, especially for large parts with significant maximum diameters. This technique is particularly advantageous for heavy or bulky parts where the weight needs optimal support. Motorized tools in vertical lathes enable precise machining operations on the outer surface of components with great flexibility for varied production series.

Internal Turning

Internal turning is essential for adjusting the internal diameter of parts such as tubes or rings to ensure precise tolerances. Using an adjustable boring tool, this method creates internal holes with exact dimensions, meeting tolerance requirements for the most demanding applications. Internal turning is crucial in the production of components where the precision of the internal diameter is key to the final assembly.

Turning with Motorized Tools

The integration of motorized tools into CNC turning allows multiple machining operations to be combined in a single step, improving efficiency and reducing cutting time. These motorized tools can be used to machine complex components in one pass, working on both the outer and inner surfaces of the part. This capability is especially beneficial for production series requiring varied geometries and impeccable finishes.

These CNC turning methods illustrate the flexibility and sophistication of modern machining technology, capable of meeting a wide range of industrial needs.

Outsource Your Industrial Operations

Groupe Hyperforme: What Are the Advantages of CNC Turning?

Precision and Consistency

CNC turning is renowned for its precision and consistency in producing parts. Thanks to a computerized program that controls every aspect of the turning process, turning machines can accurately replicate the desired shape of parts, even in small batches.

The main spindle maintains a constant rotation of the part, while the rotating tools follow precise paths to achieve the necessary cutting depth, minimizing surface roughness. This makes precision turning an excellent option for industries that require parts with tight tolerances and impeccable finishing quality.

Reduction in Production Costs

One of the main advantages of CNC turning lies in the reduction of production costs. Once the program is established, the turning machine can execute repetitive machining operations with remarkable efficiency, thereby reducing production time and potential errors.

The ability to produce small batches without the need for frequent equipment adjustments decreases waste and optimizes material usage, contributing to lower overall production costs. This technology also allows for complex machining operations to be completed in a single step, reducing the need for manual interventions and associated lead times.

Flexibility in Production

CNC turning offers exceptional flexibility in production capabilities, allowing for the processing of a wide range of materials and geometries. Modern turning machines, equipped with powerful motors and precise main spindles, can adjust cutting depth and feed rate based on material specifications and the desired shape.

This quick adaptability makes CNC turning an excellent option for complex machining operations, where frequent adjustments are needed to meet diverse customer needs while adhering to production deadlines.

Improvement in Finishing Quality

Thanks to controlled feed and the precision of rotating tools, CNC turning ensures excellent surface finishing quality for machined parts. Surface roughness is significantly reduced due to the consistency and precision of the machine’s movements, resulting in a better-quality finished product.

This is particularly important in sectors where surface finishing is crucial for the proper functioning of components, such as aerospace or automotive. This machining technology guarantees a smooth and uniform finish, reducing the need for post-machining treatments and improving overall production efficiency.

Acceleration of Production Lead Times

Finally, CNC turning allows for a significant acceleration of production lead times. With the automation of the turning process and the integration of advanced programming systems, turning machines can operate 24/7 without interruption, maximizing productivity.

This ability to continuously produce parts, with rapid changes to machining operations as needed, enables companies to respond more quickly to customer demands, reduce time-to-market, and enhance their competitiveness.

Types of CNC Turning Machines

Horizontal CNC Lathes

- The best option for machining cylindrical parts where both the outer diameter and inner diameter need to be precisely machined.

- Ideal for radial cuts and producing final products with tight tolerances.

- Capable of handling various turning materials, from metal to plastics, depending on project needs.

Vertical CNC Lathes

- Perfect for heavy or bulky parts where gravity helps keep the piece in place.

- Designed to machine large quantities of metal, particularly for oversized components.

- Ideal for final products requiring high stability and precision in machining outer diameters.

Twin-Spindle Lathes

- Allows simultaneous machining of two opposing surfaces, improving efficiency for complex final products.

- Reduces changeover time, which is essential for significant quantities of metal and short production lead times.

Multi-Axis Lathes

- Incorporates multiple axes of movement, allowing for complex radial cuts and simultaneous machining of multiple surfaces.

- The best option for parts requiring complex machining of both outer and inner diameters in a single operation.

These different types of CNC turning machines offer tailored solutions to a wide range of industrial needs, depending on the characteristics of the turning material, machining dimensions, and final product specifications.

Frequently Asked Questions About CNC Machining

What is the Quality Level of Products Obtained by CNC Machining?

CNC machining offers an exceptional product quality level, thanks to the precision of machines and software tools that control every step of the process. This allows for the production of parts with impeccable surface finishes and precise dimensions, ensuring consistent quality from one part to another, even for complex turning operations.

What is the Maximum Diameter that Can Be Machined with a CNC Machine?

The maximum diameter that can be machined depends on the specific capacity of the CNC machine used. Some machines can handle very large-diameter parts, while others are better suited for smaller pieces. It is essential to check the machine specifications to ensure it can process the required dimensions for your project.

How Does CNC Machining Influence Machining Costs?

CNC machining can optimize machining costs by reducing production cycle time and minimizing human errors. Through automation and the use of advanced software tools, turning operations and other machining processes are performed with high efficiency, reducing material waste and the need for rework.

How Does CNC Machining Fit into a Production Cycle?

CNC machining integrates effectively into a production cycle thanks to its ability to automate and standardize manufacturing processes. The software tools used to program the machines facilitate quicker production ramp-up and ensure repeatability from one part to another. This helps reduce lead times and increase productivity while maintaining a high level of product quality.

Groupe Hyperforme: CNC Turning and Machining Services

At Groupe Hyperforme, we offer a comprehensive range of CNC machining solutions designed to meet the diverse requirements of the manufacturing industry. Thanks to our state-of-the-art equipment, we guarantee high-precision CNC machining with consistent quality.

With over 800 active clients and an average daily production of more than 58,000 products, our team provides reliable and comprehensive subcontracting services, perfectly tailored to the needs of modern manufacturers.

To stay updated on the latest news, follow us on our social media channels and join our online community: