Guide to Industrial Machining: Techniques, Advantages & Applications

Industrial machining is at the heart of many modern design and production projects. In this comprehensive guide to industrial machining, we explore the various techniques used, the advantages they offer, and the recent innovations that are revolutionising the sector. Industrial outsourcing plays a crucial role in this field, allowing companies to delegate certain stages of their production to experts with the necessary equipment and skills.

What is industrial machining?

Industrial machining is a key area of manufacturing that involves shaping parts made of metal, plastic, or other materials by removing material using specialised machines. This process is essential in many sectors, from aerospace to automotive, as well as in consumer goods manufacturing. Machining processes include various techniques such as milling, turning, drilling, and grinding.

These methods allow for the creation of parts with remarkable precision and finish, thereby meeting the strict design and performance requirements. Industrial machining relies on machining expertise accumulated over the years, combined with the judicious use of modern equipment. This equipment enables the automation and control of operations with unparalleled precision.

Additionally, processes like welding can be integrated to assemble machined parts, thereby expanding production capabilities. To excel in this field, solid experience is essential. Professionals must master not only the machines and technologies but also understand the properties of materials and the specific requirements of each project.

Simplify your industrial operations with Groupe Hyperforme

Groupe Hyperforme: Industrial machining techniques

Industrial machining encompasses a variety of techniques that allow manufacturers to shape materials with high precision. Here are some of the main types of machining used in the industry:

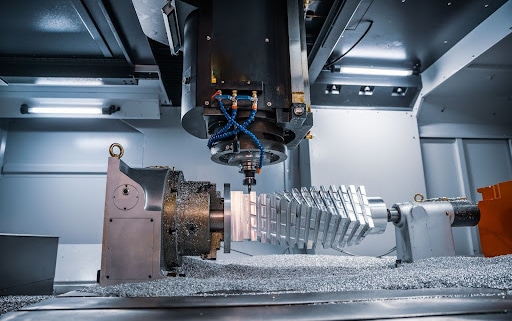

1. CNC machining (Computer numerical control)

CNC machining is one of the most advanced and precise methods available today. Using computer-controlled machines, this process enables the production of complex parts with great accuracy and repeatability. Computer programs guide the movements of cutting tools, ensuring unmatched precision in part production. CNC machining centres can handle various materials, from aluminium to stainless steel, as well as technical plastics.

2. Digital machining

Digital machining represents a revolution in industrial manufacturing by integrating cutting-edge technologies to automate and optimise the production process. By using computer-controlled systems, digital machining allows for the execution of complex operations with unprecedented precision and efficiency.

This includes various techniques such as CNC machining, laser cutting, water jet cutting, and even some 3D printing methods. Digital machining offers enhanced flexibility, allowing for rapid adjustments and custom productions to meet the specific needs of each project.

3. CNC turning

CNC turning is an advanced manufacturing method that uses computer-controlled machine tools to turn cylindrical parts with remarkable precision and efficiency. This technique allows for the production of complex components made of metal, plastic, or other materials by removing material very precisely through detailed computer programs. Furthermore, it allows for quick and flexible changes between different operations and configurations, making it ideal for small batches or customised productions.

4. CNC milling

CNC milling (Computer Numerical Control) is a manufacturing technique where computer-controlled machine tools gradually remove material from a raw piece to create complex shapes and surfaces with high precision. Primarily used to work with materials such as metal, plastic, and wood, CNC milling allows for various operations such as drilling, grooving, and profiling. Through sophisticated computer programs, this method offers exceptional repeatability and impeccable finishing quality while minimising human errors.

5. Drilling

Drilling involves creating holes in the material using drill bits. This operation is essential in the manufacturing of components that require holes for assembly or other functions. Drills can be manual or integrated into a CNC machining centre for greater precision.

6. Grinding

Grinding is a finishing process that uses an abrasive wheel to improve the surface of a machined part. This technique is used to achieve very tight tolerances and obtain a high-quality finish.

7. Electrical discharge machining (EDM)

Electrical discharge machining is a process that uses electrical discharges to remove material. It is particularly useful for machining complex shapes and very hard materials that would be difficult to work with traditional methods.

Each type of machining has its own advantages and applications, and the choice of method depends on the specific project requirements, the materials used, and the available equipment. Thanks to CNC machining and other modern techniques, industrial machining continues to evolve, offering precise and effective solutions for a variety of industrial needs.

Boost your efficiency by collaborating with Groupe Hyperforme

Importance of Machining in Modern Industry

Machining plays a crucial role in modern industry by enabling the precise and efficient transformation of raw materials into complex components essential for various sectors. Through advanced techniques such as precision machining and digital cutting, it is possible to produce parts with very fine tolerances, thereby meeting the stringent requirements of industries such as aerospace, automotive, and medical.

Machining also allows for great flexibility in design and manufacturing, facilitating custom production and rapid adaptation to technological innovations. Additionally, by improving efficiency and reducing production costs, machining supports companies’ competitiveness and fosters the development of new industrial solutions.

Groupe Hyperforme: Advantages of outsourcing for industrial machining

Outsourcing in the field of industrial machining offers numerous benefits for companies, particularly when it comes to cutting, machining processes, and precision machining. Here’s an overview of the main advantages of this practice.

Expertise and experience

Machining companies typically have years of experience and the required expertise to carry out complex tasks such as mechanical repair and industrial welding. By outsourcing these tasks to specialists, companies benefit from in-depth knowledge and skills without needing to invest in internal training.

Access to precision machines

Outsourcing also allows access to state-of-the-art industrial and precision machines. Machining companies often possess specialised equipment, such as digital cutting machines and tools for advanced machining processes, which improve the quality and efficiency of projects.

Flexibility and production capacity

Subcontractors offer increased flexibility in terms of production capacity. Whether for large projects or custom productions, these companies can adjust their production line to meet their clients’ specific needs. This optimises production without the constraints of limited internal capacity.

Reduction of production costs

By outsourcing certain machining departments, companies can significantly reduce their production costs. Subcontractors offer services at competitive rates, enabling companies to save money while benefiting from high-quality work.

Tailored approach and custom production

Subcontracting machining companies often provide a personalised approach, capable of adapting to clients’ specific requirements. They can manage custom productions, thus meeting the unique needs of each industrial project.

Focus on core business

By delegating machining tasks, companies can concentrate more on their core business. This allows them to optimise their internal resources and focus on strategic aspects of their operations, such as developing new products or expanding their market.

Outsource your industrial operations

Applications of industrial machining

- Aerospace: Manufacturing precise components for aircraft, helicopters, and drones.

- Automotive: Production of parts for engines, transmissions, and suspension systems.

- Medical: Creation of surgical instruments, implants, and high-precision medical equipment.

- Electronics: Machining of components for electronic devices, printed circuit boards, and enclosures.

- Energy: Manufacturing of parts for turbines, generators, and renewable energy production equipment.

- Agriculture: Production of components for agricultural machines, processing, and harvesting equipment.

- Construction: Machining of parts for construction machinery, lifting equipment, and tools.

- Military: Manufacturing components for weapons, armoured vehicles, and defence equipment.

- Marine: Production of parts for ships, submarines, and navigation equipment.

- Aerospace: Creation of components for satellites, space launch vehicles, and space stations.

- Rail: Machining of parts for trains, railway tracks, and railway equipment.

- Consumer goods: Manufacturing components for household appliances, tools, and sporting equipment.

- Robotics: Production of parts for industrial robots, articulated arms, and automated systems.

- Telecommunications: Machining of components for telecommunication towers, satellites, and network infrastructure.

- Textiles: Manufacturing parts for weaving, spinning, and textile processing machines.

Groupe Hyperforme: Industrial machining services

Groupe Hyperforme offers a comprehensive range of CNC machining solutions to meet the diverse needs of the manufacturing industry. With our state-of-the-art equipment, we ensure high-precision CNC machining with consistent quality. With over 800 active clients and an average daily production of more than 58,000 products, our team provides reliable and comprehensive subcontracting services, perfectly tailored to the current needs of manufacturers.

To stay informed about the latest news, follow us on our social media and join our online community: